Spotlight Wiring Harness Wholesale Solutions for Manufacturers and Suppliers

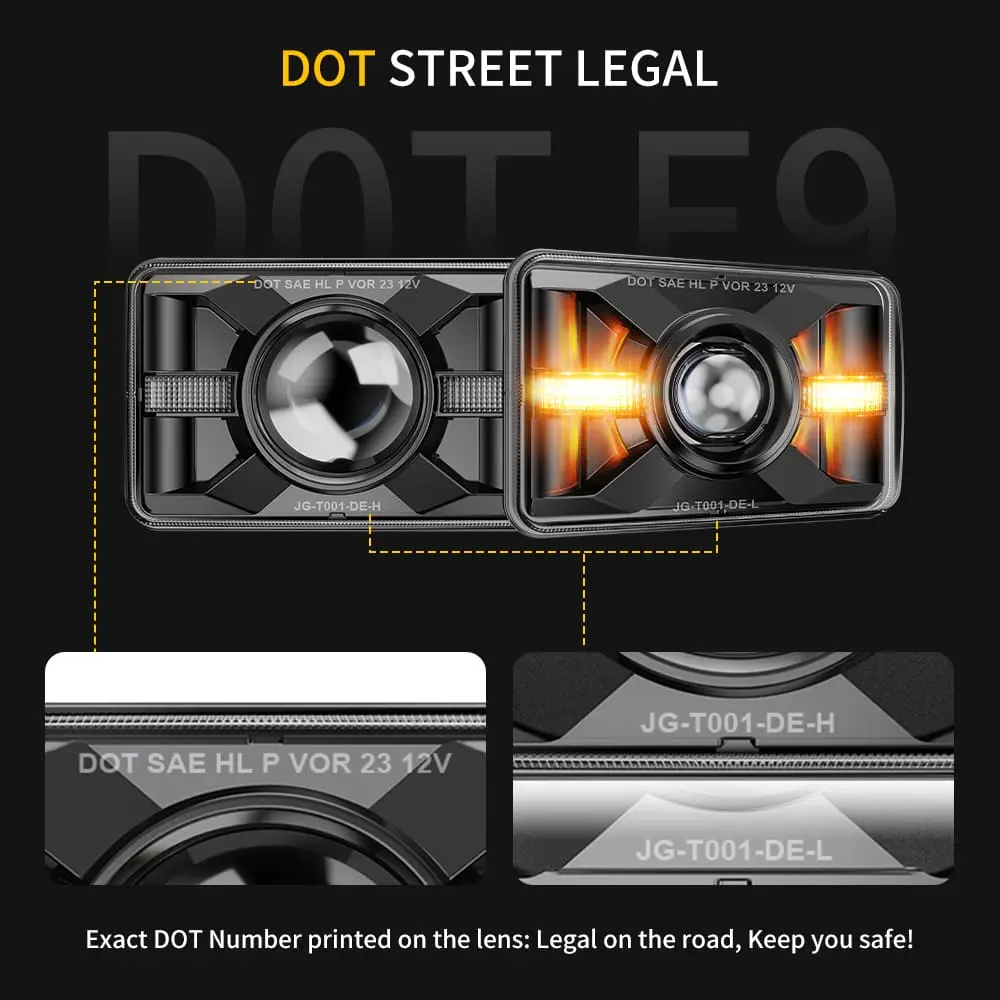

The Jiuguang Lighting Co., Ltd. Spotlight Wiring Harness is designed for superior performance and reliability in various lighting settings. This expertly crafted wiring harness facilitates seamless connectivity, ensuring optimal power distribution to high-intensity spotlights. Made from premium materials, it is resistant to heat, abrasion, and corrosion, which greatly enhances its durability and lifespan. Installation is straightforward, making it easy for both professional installers and DIY enthusiasts. Committed to safety and efficiency, this product meets rigorous industry standards, offering reassurance for all lighting projects. Whether utilized in outdoor settings, vehicles, or commercial spaces, Jiuguang Lighting's Spotlight Wiring Harness guarantees brilliant illumination and consistent operation. Enhance your lighting setup with reliable wiring solutions tailored for diverse applications. Rely on Jiuguang Lighting Co., Ltd. for innovative products that illuminate your environment.Must-Know Tips For Spotlight Wiring Harness Factory Pioneers in the Field Factory

When it comes to sourcing high-quality wiring harnesses for off-road vehicles, understanding the nuances of the manufacturing process can set you apart as a pioneer in the field. Jiuguang Lighting, with 15 years of expertise in producing automotive lighting, has honed its skills not only in light fixtures but also in the advanced accessories that make them function seamlessly. As global buyers seek reliable partners, focusing on the following must-know tips can significantly enhance your procurement strategy. Firstly, prioritize factories that demonstrate a commitment to technological innovation. Jiuguang Lighting has established itself by developing high-tech products that not only meet industry standards but also push the boundaries of performance. As a buyer, evaluating a factory's investment in research and equipment is crucial; look for suppliers who can provide updates on product enhancements and adaptations to new technologies, ensuring you stay at the forefront of the market. Secondly, fostering strong relationships with suppliers is essential. At Jiuguang, we believe in maintaining open lines of communication and transparency with our partners. This approach not only helps in meeting your immediate needs but also allows for collaborative developments tailored to specific applications, improving overall efficiency and product effectiveness. By prioritizing partnerships with manufacturers who value collaboration, you can secure a supply chain that is adaptable and responsive to market changes.

Must-Know Tips For Spotlight Wiring Harness Factory Pioneers in the Field Factory

| Tip | Description | Importance Level | Implementation Time |

|---|---|---|---|

| Choose Quality Materials | Use high-grade wiring and connectors to ensure durability. | High | Immediate |

| Regular Testing | Conduct regular testing of harness performance to identify issues early. | Medium | Weekly |

| Employee Training | Train employees on the best practices for harness assembly. | High | Monthly |

| Adopt Automation | Utilize automated equipment for precise and quick assembly. | High | Three Months |

| Feedback Loops | Establish feedback from quality control to continuously improve processes. | Medium | Ongoing |